Reactor System

-

Fisco-1SP

Reactor System

Description: Fisco lab reactors have a working capacity of 1 L, 2 L, 5 L and 10 L, suitable for dispersing, emulsifying, homogenizing, mixing, reacting, fermenting, cream perpetrating, polymerizing, and synthesis reacting under vacuum or pressurized conditions. Incorporating a macro mixing system, micro emulsifying system, vacuum system, temperature control system, and multi-sensor detecting system, they can fully simulate industrial production.

-

Fisco-2SP

Reactor System

Description: Fisco lab reactors have a working capacity of 1 L, 2 L, 5 L and 10 L, suitable for dispersing, emulsifying, homogenizing, mixing, reacting, fermenting, cream perpetrating, polymerizing, and synthesis reacting under vacuum or pressurized conditions. Incorporating a macro mixing system, micro emulsifying system, vacuum system, temperature control system, and multi-sensor detecting system, they can fully simulate industrial production.

-

Fisco-5SP

Reactor System

Description: Fisco lab reactors have a working capacity of 1 L, 2 L, 5 L and 10 L, suitable for dispersing, emulsifying, homogenizing, mixing, reacting, fermenting, cream perpetrating, polymerizing, and synthesis reacting under vacuum or pressurized conditions. Incorporating a macro mixing system, micro emulsifying system, vacuum system, temperature control system, and multi-sensor detecting system, they can fully simulate industrial production.

-

Fisco-1S

Reactor System

Fisco lab reactors have a working capacity of 1 L, 2 L, 5 L and 10 L, suitable for dispersing, emulsifying, homogenizing, mixing, reacting

-

Fisco-1S-A

Reactor System

Fisco lab reactors have a working capacity of 1 L, 2 L, 5 L and 10 L, suitable for dispersing, emulsifying, homogenizing, mixing, reacting

-

Fisco-2S

Reactor System

Fisco lab reactors have a working capacity of 1 L, 2 L, 5 L and 10 L, suitable for dispersing, emulsifying, homogenizing, mixing, reacting

-

Fisco-2S-A

Reactor System

Fisco lab reactors have a working capacity of 1 L, 2 L, 5 L and 10 L, suitable for dispersing, emulsifying, homogenizing, mixing, reacting

-

Fisco-5S

Reactor System

Description: Fisco lab reactors have a working capacity of 1 L, 2 L, 5 L and 10 L, suitable for dispersing, emulsifying, homogenizing, mixing, reacting, fermenting, cream perpetrating, polymerizing, and synthesis reacting under vacuum or pressurized conditions. Incorporating a macro mixing system, micro emulsifying system, vacuum system, temperature control system, and multi-sensor detecting system, they can fully simulate industrial production.

-

Fisco-5S-A

Reactor System

Description: Fisco lab reactors have a working capacity of 1 L, 2 L, 5 L and 10 L, suitable for dispersing, emulsifying, homogenizing, mixing, reacting, fermenting, cream perpetrating, polymerizing, and synthesis reacting under vacuum or pressurized conditions. Incorporating a macro mixing system, micro emulsifying system, vacuum system, temperature control system, and multi-sensor detecting system, they can fully simulate industrial production.

-

Fisco-10

Reactor System

The new FLUKO vacuum emulsification and homogenization system is synchronized with the European classic design. It can realize the dispersion, emulsification, homogenization, mixing and other production processes of materials in a vacuum or pressure environment; both stirring and homogenization can realize positive and negative rotation, which meets the needs of external connections. Suction of powder and liquid and homogenization of internal and external circulation. The equipment specifications range from 10L to 2000L, meeting the pilot and production needs of various products.

-

Fisco-20

Reactor System

The new FLUKO vacuum emulsification and homogenization system is synchronized with the European classic design. It can realize the dispersion, emulsification, homogenization, mixing and other production processes of materials in a vacuum or pressure environment; both stirring and homogenization can realize positive and negative rotation, which meets the needs of external connections. Suction of powder and liquid and homogenization of internal and external circulation. The equipment specifications range from 10L to 2000L, meeting the pilot and production needs of various products.

-

Fisco-50

Reactor System

The new FLUKO vacuum emulsification and homogenization system is synchronized with the European classic design. It can realize the dispersion, emulsification, homogenization, mixing and other production processes of materials in a vacuum or pressure environment; both stirring and homogenization can realize positive and negative rotation, which meets the needs of external connections. Suction of powder and liquid and homogenization of internal and external circulation. The equipment specifications range from 10L to 2000L, meeting the pilot and production needs of various products.

-

Fisco-100

Reactor System

The new FLUKO vacuum emulsification and homogenization system is synchronized with the European classic design. It can realize the dispersion, emulsification, homogenization, mixing and other production processes of materials in a vacuum or pressure environment; both stirring and homogenization can realize positive and negative rotation, which meets the needs of external connections. Suction of powder and liquid and homogenization of internal and external circulation. The equipment specifications range from 10L to 2000L, meeting the pilot and production needs of various products.

-

Fisco-1H

Reactor System

Fisco-H Reactor System has working capacity of 1L, 2L, suitable for dispersing, emulsifying, homogenizing, mixing under vacuum or pressure conditions.

-

Fisco-2H

Reactor System

Fisco-H Reactor System has working capacity of 1L, 2L, suitable for dispersing, emulsifying, homogenizing, mixing under vacuum or pressure conditions. It can be equipped with various of high-efficiency macro mixers, high shear dispersing emulsifiers, reliable vacuum sealing system and temperature control system. A variety of sensor detection systems can simulate industrial production in a laboratory environment. For materials with high viscosity such as creams and polymers, Fisco-H series vessels can be tilted at 135℃ to facilitate the overall discharge.

FISCO Glass Reactor

-

FISCO-G10

FISCO Glass Reactor

Glass reactors are suitable for chemical reactions in laboratories and industries.

-

FISCO-G20

FISCO Glass Reactor

Glass reactors are suitable for chemical reactions in laboratories and industries.

-

FISCO-G30

FISCO Glass Reactor

Glass reactors are suitable for chemical reactions in laboratories and industries.

-

FISCO-G50

FISCO Glass Reactor

Glass reactors are suitable for chemical reactions in laboratories and industries.

-

FISCO-G100

FISCO Glass Reactor

Glass reactors are suitable for chemical reactions in laboratories and industries.

FISCO complete set of pressure-resistant reactor

-

Fisco Lab Reactor

FISCO complete set of pressure-resistant reactor

Various reaction systems can be customized according to the user's process flow and product characteristics.

It has many advantages: PLC control, high-efficiency mixing, high-speed dispersion, emulsification and homogenization, multiple feeding modes, and vacuum or pressure environment for customers to simulate real-life conditions or small-scale production.

Micro Reactor

-

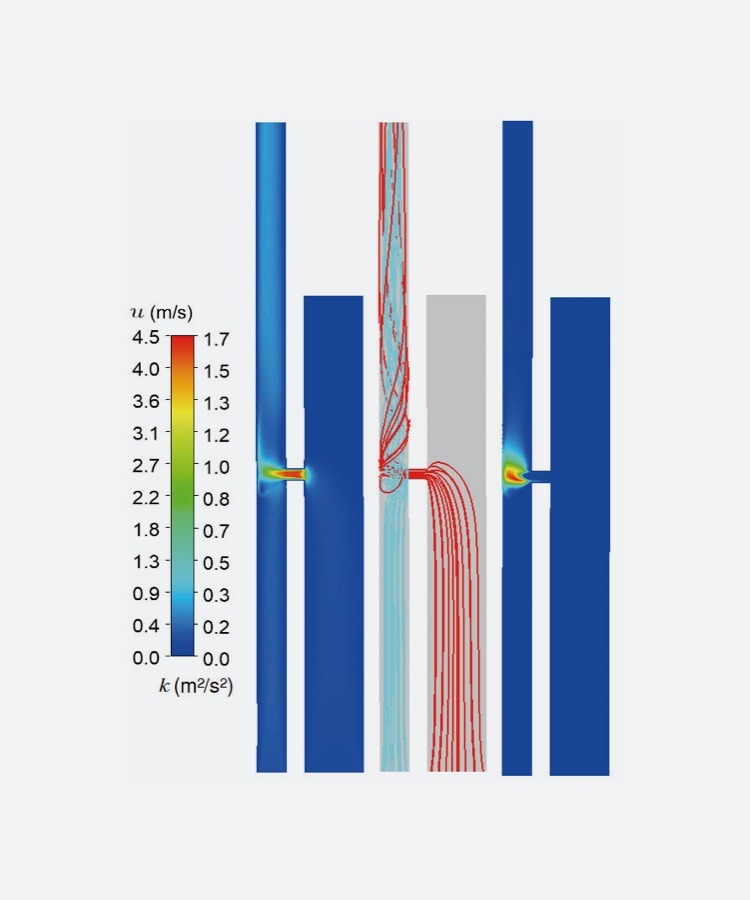

FTC Tube-in-Tube Microchannel Reactor

Micro Reactor

Tube-in-Tube microreactor is another kind of high-throughput microchannel reactor

-

FT Microreactor

Micro Reactor

"Trigram-fish-shaped microreactor" FT series are the microchannel reactors independently developed by the collaboration of FLUKO and Tianjin University