compare

compare

MiFlow Insight 100

The MiFlow Insight 100 is a scientific instrument for high-resolution imaging and automated statistical analysis of suspended particles in liquids.

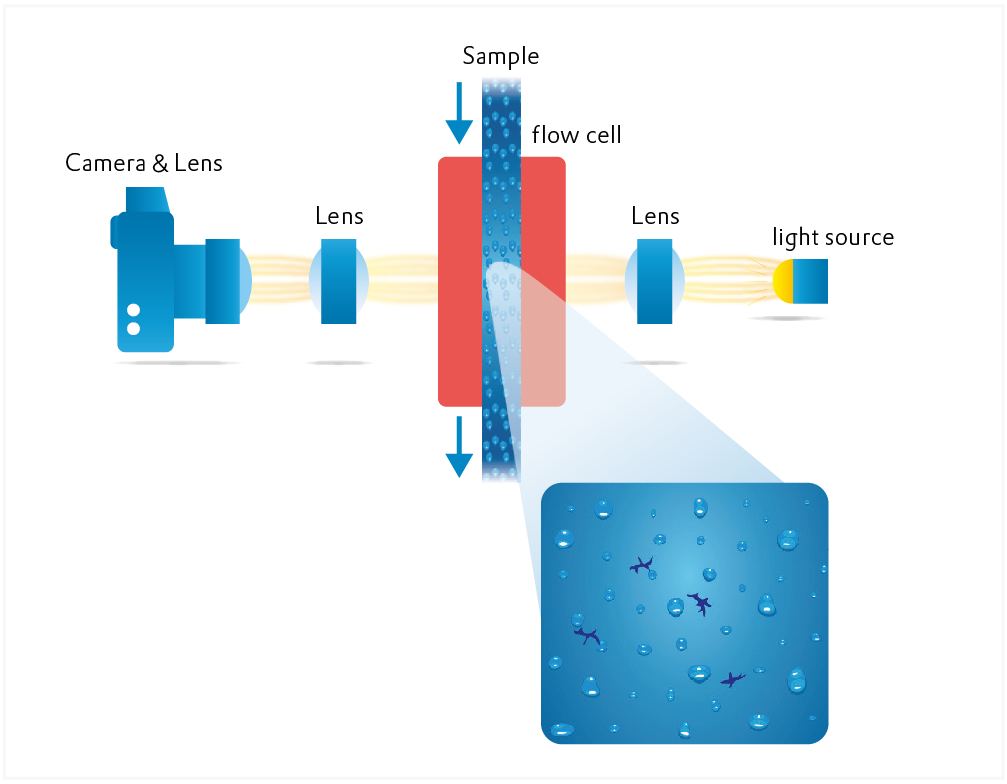

Its core principle involves allowing a sample to flow through a transparent microfluidic channel, capturing high-frequency images of each passing particle in a specific area, and then using AI to classify and statistically analyze the acquired images. This automated system can obtain diverse information related to particles, such as particle size, shape, statistics, and substance identification.

Main Features

Automated workflow: Automatically performs sample loading, cleaning, detection and analysis, enabling automatic analysis of over 96 consecutive samples.

Wide dynamic range: Supports samples with a linear range of 500~5,000,000 particles/mL, and deducts adherent particles in real time.

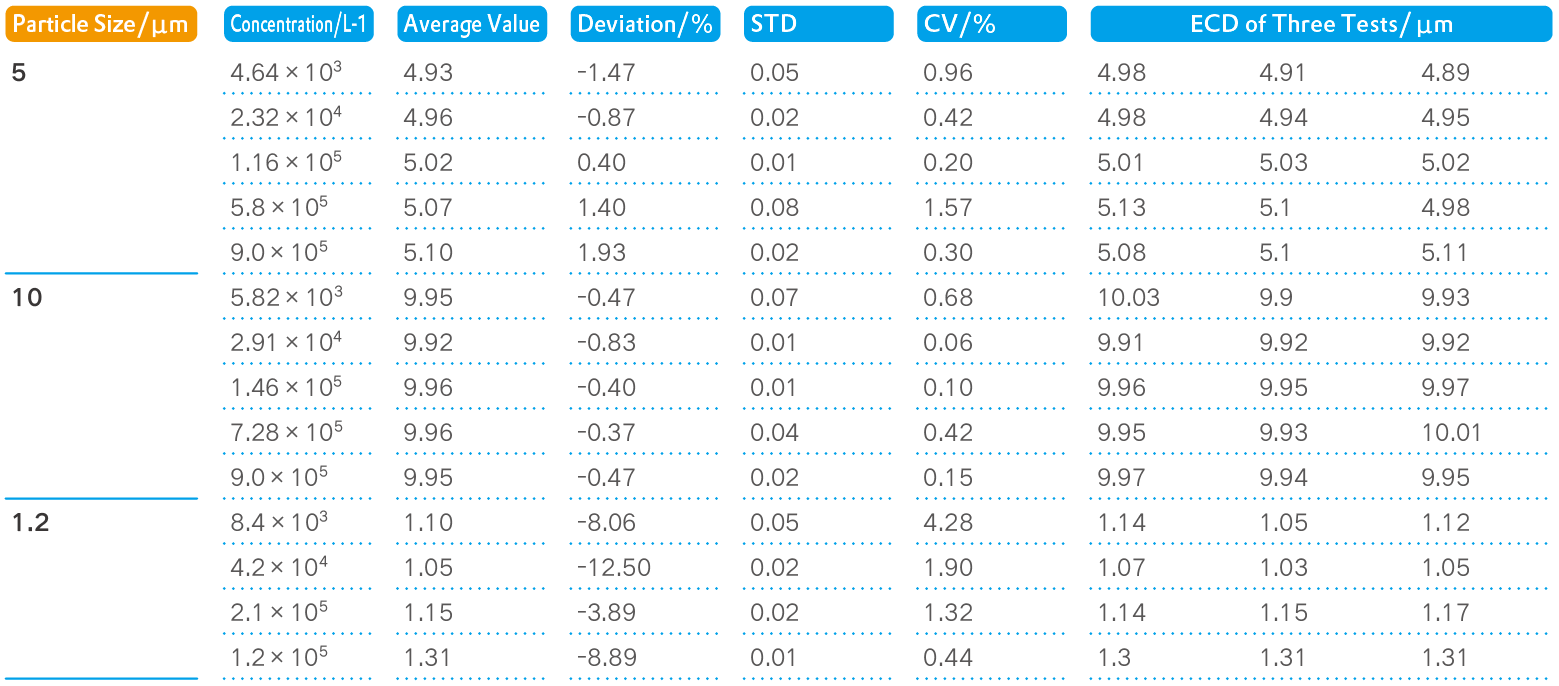

Reproducible results: For ECD experiments, the measured RSD is less than 5%.

Flexible configuration: Offers customizable automatic test workflows to adapt to different testing and analysis requirements.

Ultra-high definition imaging: Equipped with a 25-megapixel camera and a high-resolution telecentric lens, achieving a resolution of 0.25μm, with a large depth of field and no motion blur for moving particles.

Large field-of-view volume: Adopts a quartz glass flow cell that is durable and easy to clean, ensuring high sample throughput and high coverage rate.

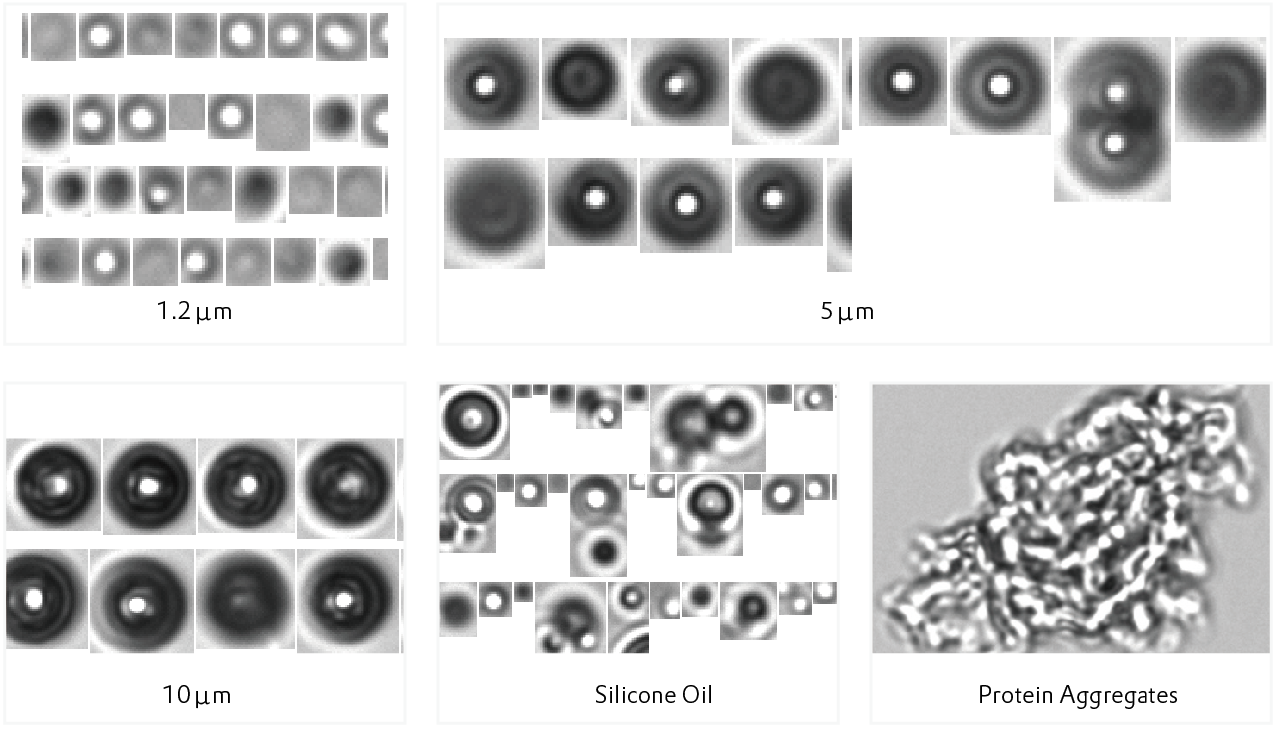

AI Classification

Using AI algorithms, images are recognized, categorized, and counted, intelligently distinguishing between particles and non-particles.

Panoramic Depth Imaging

All particles are within the depth of field, ensuring high coverage and accuracy in sample detection.

Application Fields

Flowable Material Testing:

Suitable for a wide range of flowable materials, enabling the detection of submicron-scale particle information.

Formulation Development:

Investigating the effects of buffer solutions, protein drug concentrations, excipient addition and other factors on particle formation.

Formulation Stability:

Studying particle formation under various stress conditions.

Sub-particle Identification:

Due to the limitation of Light Obscuration (LO) in missing the detection of highly transparent subvisible particles, microfluidic imaging technology is adopted to classify glass, air bubbles, silicone oil, rubber debris, plastic particles and protein particles.

Packaging Material Qualification:

For the primary packaging materials of implantable sterile medical devices, the acceptable levels of initial microbial contamination and particulate contamination shall be determined and documented.

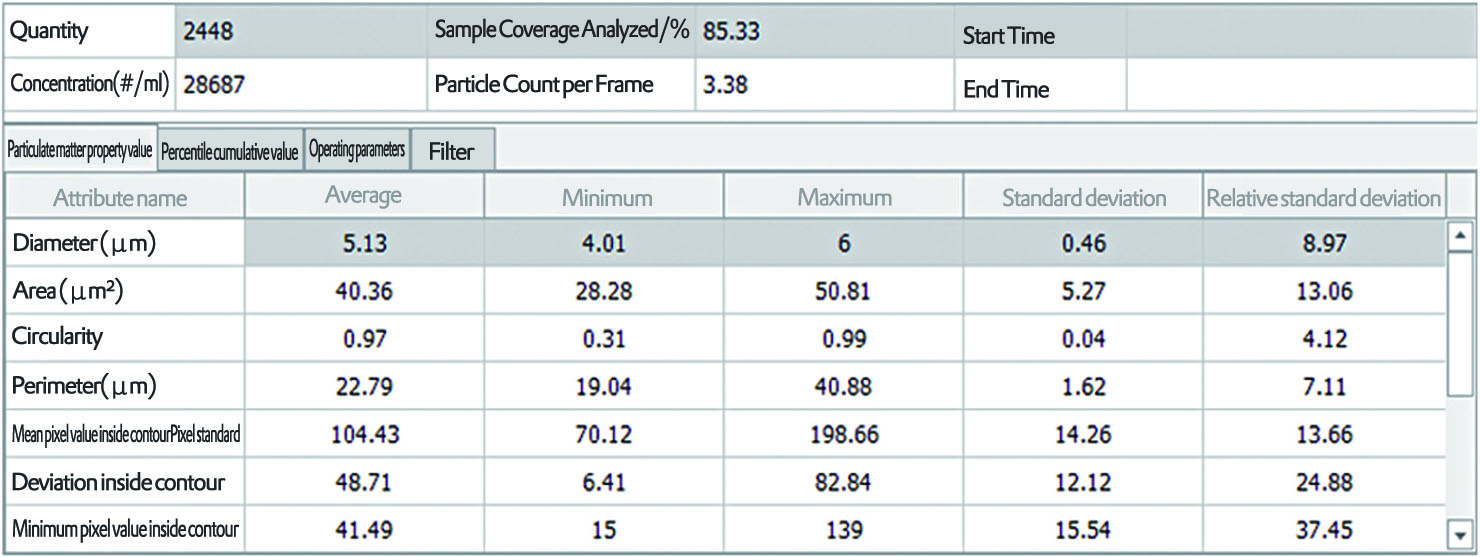

Particle Repeat Measurement Test (ECD)

Real-time observation available:The heat map displays the distribution of particulate matter within the flow cell in real time.

TECHNICAL PARAMETER

| Instrument Model | MiFlow Insight 100 |

| Equipment Power | 350 W |

| Detection Principle | Dynamic imaging method |

| Detection Range | 1-100 μm |

| Flow Rate Range | 100 ul/min~48000 ul/min |

| Lens Type | High-resolution telecentric lens 0.25 μm resolution |

| Camera Resolution | 25 million pixels |

| Light Source | Monochrome LED light source |

| Software Type | AI intelligent analysis software |

| Flow Cell Material | Quartz glass |

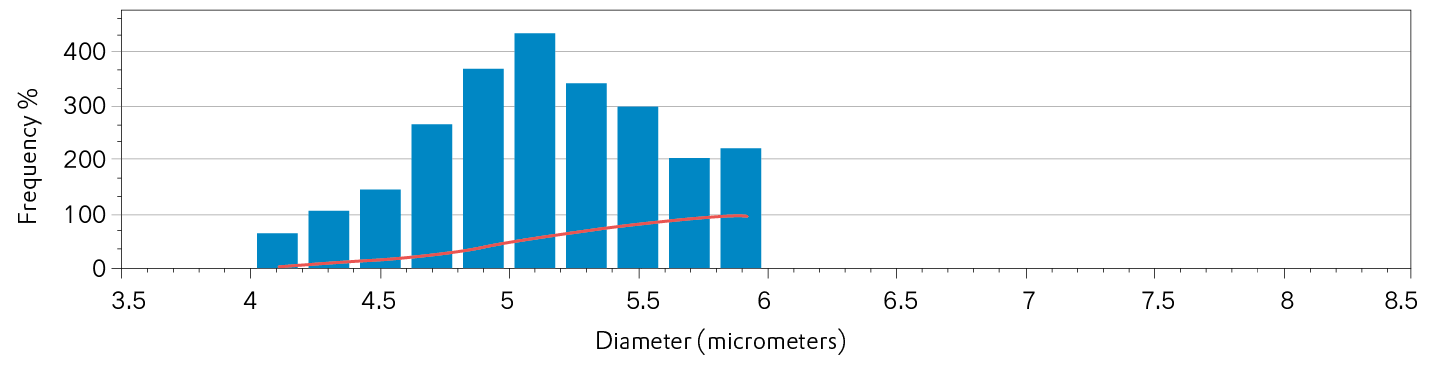

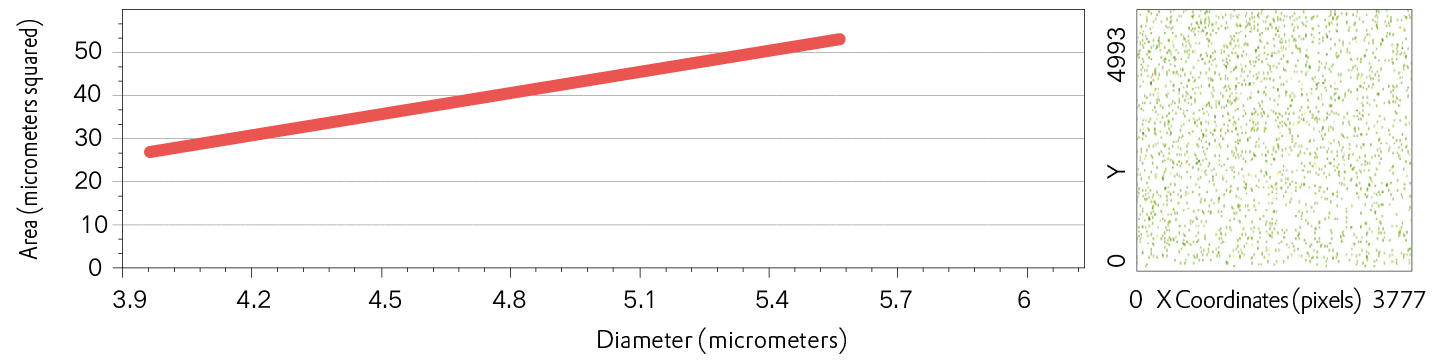

| Morphological Parameters | Morphological parameters include equivalent ECD, area, perimeter, average pixel value, pixel STD, maximum pixel value, minimum pixel value, convexity, compactness, elongation, roughness, aspect ratio, maximum Fret diameter, symmetry, transparency, eccentricity, roundness |

| Working Computer | Built-in |

| Equipment Weight | 50 KG |

| Product Dimensions | Overall dimensions (mm): L509.5 x W459.5 x H764.5Main unit (mm): L509.5 x W459.5 x H257.5Autosampler (mm): L509.5 x W459.5 x H507 |